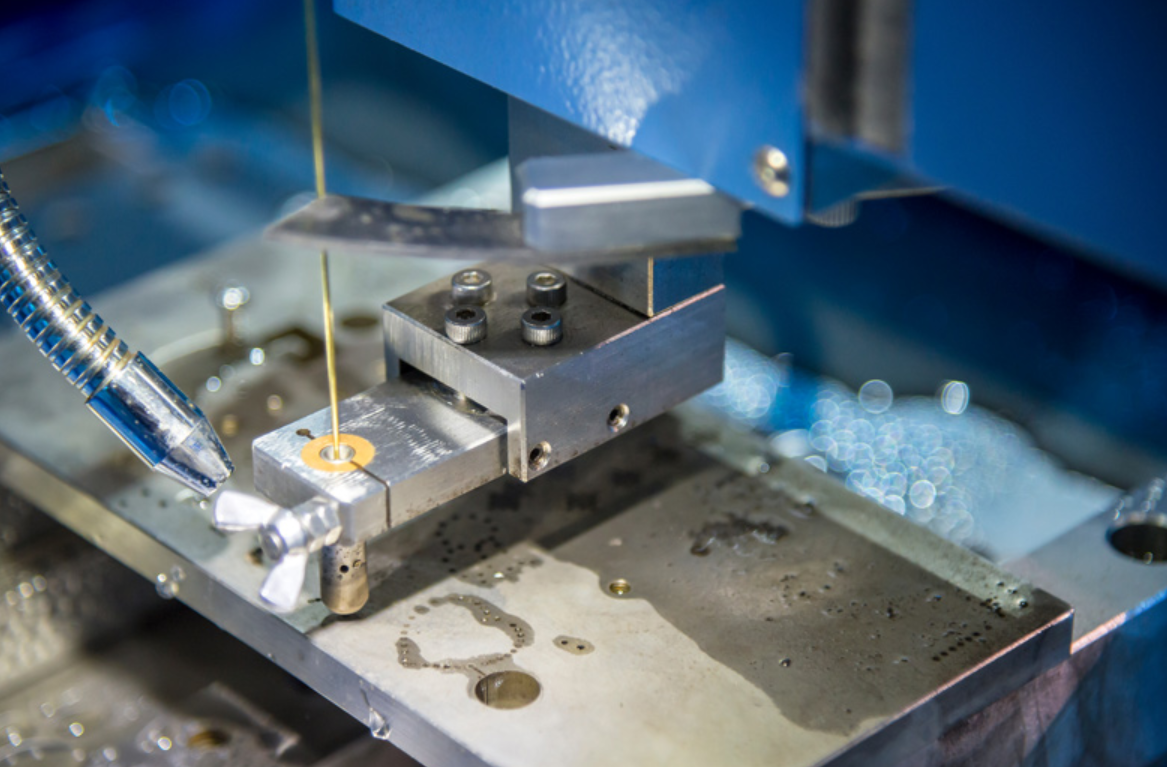

Mold making is a specific industry and for companies to be productive, they need to use special machines. These machines need to be maintained and if they are not, this can take a toll on their business. When you think about the areas where productivity can be improved, wire EDM comes as the most obvious place to start.

These are pretty easy to deal with unlike some other areas of business such as programming methods or tooling methods, where you would need to do an entire reconstruction.

In order to improve productivity, you must not let your wire EDM sit while you do all the manual labor to prepare it for the next cut. Therefore, we offer you some tips on how to best utilize your wire EDM to increase productivity.

Maintenance is a must

Wire EDM has a lot of wear parts that need to be replaced after some time. Maintaining the machine is crucial for its longevity. If you forget to do these things, there is a higher chance for the machine to break over time and then you will have much bigger issues to deal with.

Therefore, we suggest you keep a logbook on these machines and its parts. And if you need EDM filters, you know where to get those.

Keep the Machine Running

This goes without saying, but if you want to increase the wire EDM productivity, you need to keep the machine running as much as possible. Figure out a way how to adjust your operations to the machine so that you can use it throughout the day.

This, together with regular maintenance is crucial to increasing productivity. You don’t want to face any unnecessary bottlenecks and damages and have the machine sit there for days.

Look at these as your car. If you leave your car sit for weeks over and over again, eventually they will deteriorate. Cars are meant to be drive and these machines are meant to be used!

Removing slugs

Your machine doesn’t need to have time off. You can automatize the process of removing slugs and even when the shift is over, installing a software that does this will add additional hours every day and the machine can work by itself.

Not only that, but your overall operation will be more efficient. A person who has to remove slugs manually could do something else instead, while wire EDM will work for longer hours.

This ties to your customers too. They will get their products faster and you will be able to receive more orders.

Conclusion

Increasing the productivity of your wire EDM isn’t as simple as it seems, but there are definitely things that you can do to maximize its production. At the end of the day, you can talk to other companies and see what they are doing to improve their quality and add more working hours.