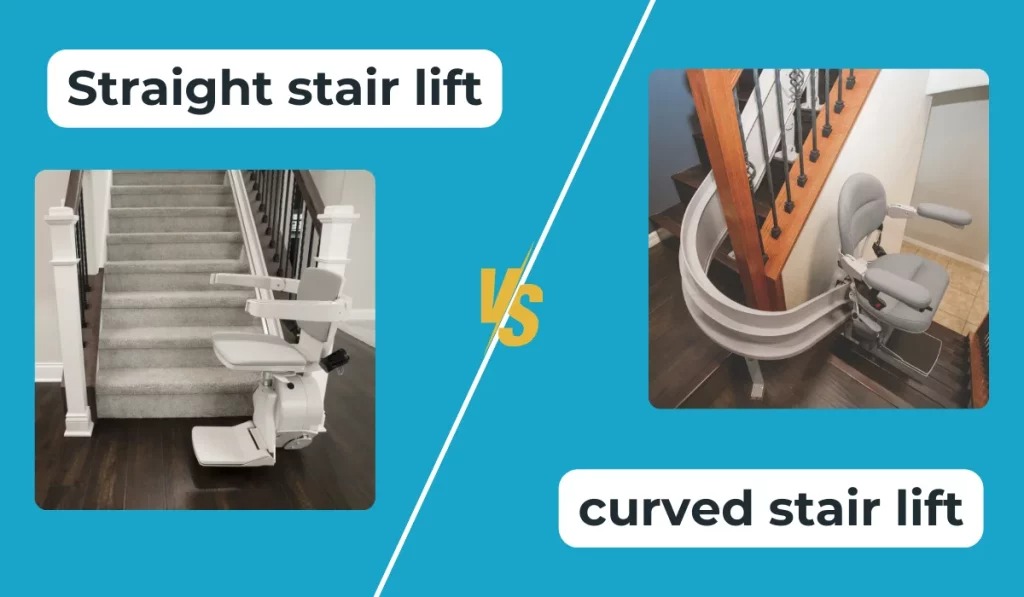

Choosing the right stairlift often comes down to how a staircase is shaped and how quickly support is needed at home.

Straight and curved models solve the same mobility problem, yet they differ in fit, price, and installation approach in ways that matter long term.

Understanding those differences helps households avoid unnecessary costs and delays while selecting a system that works comfortably every day.

The comparison below focuses on practical factors rather than sales language, giving a clear picture of what separates straight stairlifts from curved stairlifts in real homes.

Understanding Staircase Fit and Layout Compatibility

When evaluating stairlift options, staircase shape is the starting point because it directly determines which system can be installed safely.

In many UK homes, stairs run in a single line with no turns, landings, or changes in width.

For these cases, straight rail systems provide a simple and predictable solution. In contrast, staircases with bends, spirals, or intermediate landings require a custom approach that follows every curve precisely.

Early in the decision process, many households begin researching Stairlifts to understand which designs are compatible with their layout and daily mobility needs.

Straight models are manufactured in standard lengths and adjusted on site, while curved systems are built to measure using detailed surveys.

That difference in fit explains why curved options feel more integrated but also more complex.

Fit is not only about physical space but also about how naturally the lift moves along the stairs without abrupt stops or awkward seating positions.

Cost Differences and What Drives Pricing

Price variation between straight and curved stairlifts often surprises buyers, so it helps to understand what contributes to the final figure.

Straight models benefit from standardization, which keeps production and installation costs lower.

Curved systems involve custom engineering, digital measurements, and specialized rails that increase both labor and materials.

To clarify what affects pricing, the following points highlight the main cost drivers buyers typically encounter:

- Rail design complexity, since curved rails are made specifically for one staircase

- Survey and manufacturing time, which is longer for non standard layouts

- Installation labor, as curved systems require more precise fitting

- Future adjustments, which are easier and cheaper on straight systems

A helpful reference point is the general industry definition below

A curved stairlift uses a bespoke rail manufactured to match the exact angles, turns, and gradients of a staircase, making it unique to a single property and not reusable elsewhere.

Understanding these elements helps explain why curved options command a higher upfront investment.

Installation Time and Household Disruption

Installation speed is another key difference that often influences decision making, especially when mobility support is needed quickly.

Straight stairlifts usually arrive ready to fit, allowing trained installers to complete the job within a few hours.

The process involves securing the rail to the stair treads, mounting the chair, and testing safety features.

Curved stairlifts follow a longer timeline. After an initial survey, the rail must be manufactured off site, which can take several weeks.

Installation itself also takes longer because every section must align perfectly. To give a clearer comparison, the table below outlines typical timelines and installation factors.

| Feature | Straight Stairlift | Curved Stairlift |

| Rail production | Standard length | Custom built |

| Average install time | Same day | One full day or more |

| Pre install waiting period | Minimal | Several weeks |

| On site adjustments | Limited | Extensive |

After installation, curved systems often require additional testing, which slightly extends household disruption.

Daily Use Experience and Practical Considerations

Beyond fit and cost, everyday usability shapes long term satisfaction. Straight stairlifts offer consistent movement and fewer mechanical variables, which can translate into simpler maintenance over time.

Controls are usually straightforward, and servicing is widely available due to the standardized design.

Curved stairlifts provide a smoother ride on complex staircases, especially where tight turns or narrow landings exist.

A useful way to evaluate daily comfort is to consider the following practical aspects that influence user experience:

- Seating position at landings, which can be customized on curved models

- Travel smoothness around corners, reducing abrupt motion

- Space usage, as curved rails often hug the staircase more closely

- Visual integration, since custom rails tend to look more tailored

Did you know many curved systems include powered swivel seats as standard to improve safety at the top landing.

Such features can be added to straight models, but they are more commonly built into curved designs due to layout demands.

Conclusion

Straight and curved stairlifts address different structural realities rather than competing directly.

Straight systems suit simple staircases, offer faster installation, and remain the most cost conscious option.

Curved systems adapt to complex layouts and provide tailored movement at a higher price and longer lead time.

The right choice depends on staircase design, urgency, and long term comfort expectations.

Evaluating fit, cost drivers, and installation timing together ensures the selected stairlift supports daily mobility without compromise.