Laser cutting has become an essential technology in various industries, offering unparalleled precision and versatility. This advanced technique utilizes a highly concentrated beam of light to cut through materials accurately and quickly. From metals to fabrics and everything in between, laser cutting services have revolutionized how we design, manufacture, and create intricate designs.

1. The Mechanics Behind Laser Cutting Technology

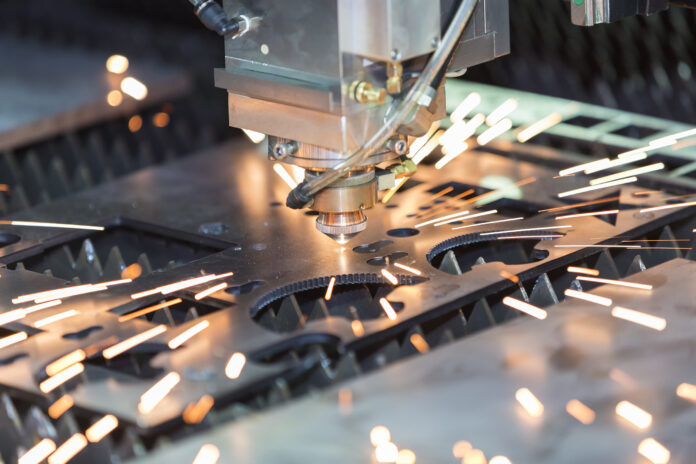

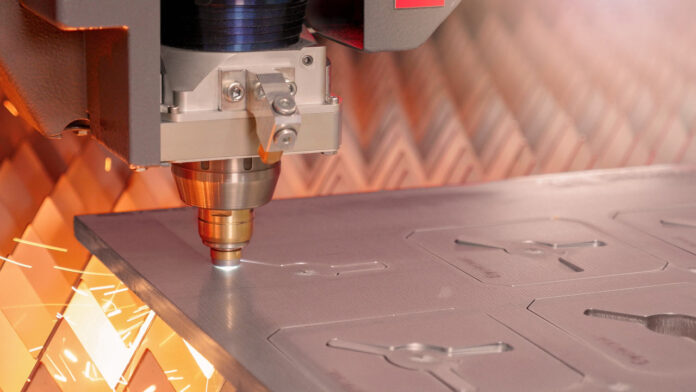

At the heart of laser cutting technology is a focused beam of light generated by a laser source. This beam is directed towards the material, melting, burning, or vaporizing it along a predetermined path. The laser’s high intensity and pinpoint accuracy ensure clean and precise cuts, even on complex shapes and intricate patterns. The process is controlled by Computer Numerical Control (CNC) systems, which use digital files to guide the laser and achieve the desired outcome.

Various types of lasers can be used for cutting, including CO2, Nd: YAG, and fiber lasers. Each type has its own advantages and is suited for specific materials and cutting requirements. For example, CO2 lasers are commonly used for organic materials like wood, acrylic, and fabrics, while fiber lasers are ideal for metals and alloys.

2. Advantages of Laser Cutting Services for Industrial Applications

Laser cutting services offer numerous advantages over traditional cutting methods, making them popular for industrial applications. One of the key benefits is the precision and accuracy achieved with laser cutting. The focused laser beam ensures clean edges, tight tolerances, and intricate detailing, which is crucial for the aerospace, automotive, and electronics industries.

Another advantage of laser cutting is the ability to automate the process. Once the cutting parameters are set up in the CNC system, the laser can repetitively and consistently cut identical shapes and patterns, streamlining production processes and reducing human error. This automation also increases production capacity, as laser-cutting machines can work continuously with minimal downtime.

Laser cutting is a non-contact process, which means no physical force is applied to the material being cut. This minimizes the risk of deformation, warping, or damage to delicate or sensitive materials. The heat-affected zone (HAZ) in laser cutting is also small compared to other methods, resulting in minimal thermal distortion.

3. How Laser Cutting Has Revolutionized Design and Manufacturing

The precision and versatility of laser cutting have opened up new possibilities in design and manufacturing. Designers and engineers can now create complex patterns and intricate designs that were once difficult or impossible to achieve with traditional cutting methods. Many businesses now often rely on Precision Laser Cutting Services to achieve these high levels of detail, ensuring accuracy down to the finest millimeter. From architectural models to intricate jewelry, laser cutting allows for producing highly detailed and customized pieces.

Laser cutting has also revolutionized the prototyping process. With the ability to quickly and accurately produce prototypes, designers can iterate and refine their designs more efficiently. This helps to shorten development cycles and bring products to market faster.

Furthermore, laser cutting has enabled the customization of products on a mass scale. With digital files, personalized designs can be easily applied to various materials, allowing for unique and customized products. This has gained popularity in signage, interior design, and personalized gifts.

The Artistry of Craftsmanship: Creating Intricate Designs with Laser Cutting

Beyond its industrial applications, laser cutting also offers a world of artistic possibilities. This technology has become an essential tool for artisans, craftsmen, and designers looking to push the boundaries of creativity and craftsmanship.

1. Pushing Boundaries: Creating Complex Patterns with Laser Cutting

With laser cutting, artists and craftsmen can explore intricate and complex patterns that would be challenging or time-consuming to achieve by hand. The precision and accuracy of the laser allow for the creation of intricate lace-like patterns, geometric designs, and interlocking shapes. These intricate patterns can be applied to various materials, including wood, acrylic, paper, and leather.

Laser cutting has also provided a platform for exploring and reviving traditional craftsmanship techniques. Artisans can combine traditional handcrafted techniques with laser cutting to create contemporary pieces with a nod to the past. This fusion of old and new opens up possibilities for innovative and captivating designs.

2. The Marriage of Art and Technology: Exploring Laser Engraving

One of the standout features of laser cutting is its ability to engrave designs onto various materials. Laser engraving involves removing the surface layer of a material to create permanent markings or designs. This technique is widely used in awards, recognition, signage, and personalized gifts.

Artists and designers can use laser engraving to add intricate details, textures, and photographic imagery to their creations. The level of detail achievable with laser engraving is remarkable, allowing for fine lines and delicate shading reproduction. This has opened up new avenues for artistic expression and has become popular in creating personalized and commemorative items.

3. Customizability at its Finest: Personalization with Laser Cutting Services

Personalization has become a significant trend in various industries, and laser-cutting services offer the perfect solution for creating customized products. Whether it’s engraving names on jewelry, adding unique designs to home decor items, or personalizing promotional merchandise, laser cutting allows for easy customization on a mass scale.

The digital nature of laser cutting enables quick and easy design changes, allowing customers to personalize their products with specific names, dates, or messages. This level of customizability has gained popularity in the wedding and gifting industry, where customers are looking for unique and meaningful items.

The Wide World of Materials: What Can Laser Cutting Do?

Laser cutting is a versatile technology capable of cutting a wide range of materials, each with unique considerations and capabilities. This versatility has contributed to the widespread adoption of laser-cutting services across multiple industries.

1. From Delicate Fabrics to Rigid Metals: Laser Cutting Across Various Materials

One of the standout features of laser cutting is its ability to handle a diverse range of materials. From delicate fabrics like silk and lace to rigid metals like stainless steel and aluminum, laser cutting offers precise and clean cuts across the board.

For organic materials such as fabrics and leather, laser cutting provides unparalleled precision, enabling the creation of intricate and delicate designs. The non-contact nature of laser cutting also minimizes the risk of fraying or damage to the material.

Regarding metals, laser cutting offers advantages over traditional cutting methods. The focused laser beam can cut through thick metal sheets effortlessly, leaving smooth and burr-free edges. Laser cutting is ideal for the automotive, aerospace, and jewelry industries.

2. The Precision Difference: Smooth Edges and Clean Cuts with Laser Cutting

One of the key advantages of laser cutting is the quality of the cuts produced. The laser beam is incredibly precise, resulting in clean cuts with minimal distortion or charring. This precision allows for tight tolerances and the ability to create intricate designs easily.

In contrast to traditional cutting methods like sawing or shearing, laser cutting leaves smooth edges, eliminating the need for further finishing or polishing. This not only saves time and resources but also ensures a high-quality finish.

Furthermore, laser cutting is a non-contact process, meaning no physical force is applied to the material during cutting. This reduces the risk of damage or deformation, making laser cutting suitable for fragile or delicate materials prone to warping or distortion.

3. Unlocking the Potential: Discovering Unique Applications of Laser Cutting

While laser cutting is commonly associated with industries such as manufacturing and design, its applications go far beyond these realms. The precision and versatility of laser cutting have sparked innovation and creativity across various fields.

Laser cutting produces intricate components for medical devices, implants, and surgical instruments in the medical industry. The precision of laser cutting ensures the accuracy and reliability of these critical components, which can greatly impact patient outcomes.

Architects and designers have also embraced laser cutting for creating intricate models and prototypes. The ability to quickly and accurately produce various architectural elements allows for detailed visualizations and precise analysis.

Additionally, the automotive industry leverages laser cutting to produce vehicle components and parts. The ability to cut through different types of metals with precision and efficiency is crucial in manufacturing cars and motorcycles.

Furthermore, integrating hardware such as thumb screws with laser-cut components enhances assembly and maintenance. These allow for quick, tool-free fastening and adjustment of parts, making prototypes, fixtures, and even custom vehicle components easier to modify and secure.

Choosing the Right Laser Cutting Service for Your Needs

When considering laser cutting services, choosing a provider that can meet your specific requirements is important. Not all laser cutting services are created equal, and factors like capabilities, expertise, and project suitability should be considered.

1. Factors to Consider: Evaluating the Capabilities of Laser Cutting Providers

Before selecting a laser cutting service, evaluating their capabilities and equipment is crucial. Consider factors such as the maximum material thickness they can handle, the types of lasers they use, and the range of materials they can cut. Additionally, inquire about their precision and accuracy standards and their ability to handle complex designs or patterns.

Another important consideration is the size and capacity of their laser-cutting machines. Ensure they have the equipment to handle your project requirements and meet your desired production timeline.

2. Expertise Matters: Finding a Laser Cutting Service with Experience

Experience plays a vital role in laser cutting services. Look for providers with a track record of delivering high-quality results and satisfying customers. A reputable laser cutting service will have extensive experience working with various industries and materials, ensuring they can handle your project’s specific challenges and requirements.

Additionally, consider the expertise and knowledge of their staff. Skilled and knowledgeable operators can optimize cutting parameters, troubleshoot issues, and provide valuable insights to enhance the outcome of your project.

3. From Prototyping to Production: Matching Your Project Requirements with Laser Cutting Services

Different laser-cutting services cater to different project requirements. Some specialize in quick prototyping, while others focus on large-scale production. Consider the scale and scope of your project and ensure that the laser cutting service you choose aligns with your specific needs.

Furthermore, communication and collaboration are essential for successful project execution. Choose a laser-cutting service provider that values open communication, understands your project goals, and is willing to work closely with you to achieve the desired outcome.

In conclusion, laser-cutting services offer possibilities that combine precision, versatility, and creativity. Whether for industrial applications or artistic endeavors, laser cutting has revolutionized how we design, create, and manufacture. By understanding the mechanics behind laser cutting, exploring its artistic potential, and realizing the endless applications across materials, we can unlock the full potential of this remarkable technology. Choosing the right laser-cutting service provider ensures that your project receives the precision, expertise, and customization it deserves.

FAQ

Question: What is laser cutting? – Laser cutting technology uses a highly concentrated light beam to cut through materials precisely and accurately.

Question: What are the advantages of laser cutting services? – Laser cutting services offer precision, automation, and non-contact cutting advantages. It revolutionizes design, manufacturing, and prototyping processes, enabling customization on a mass scale.

Question: What types of lasers are used for cutting? – Various types of lasers can be used for cutting, including CO2, Nd:YAG, and fiber lasers. Each type has its own advantages and is suited for specific materials and cutting requirements.

Question: How has laser cutting revolutionized design and manufacturing? – Laser cutting has opened up new possibilities in design and manufacturing by allowing the creation of complex patterns and intricate designs that were once difficult or impossible to achieve with traditional cutting methods. It has also shortened development cycles and enabled the customization of products on a mass scale.

Question: What artistic possibilities does laser cutting offer? – Laser cutting offers the ability to create intricate and complex patterns, explore traditional craftsmanship techniques, and engrave designs onto various materials. It has become an essential tool for artisans, craftsmen, and designers looking to push the boundaries of creativity.

Question: What materials can be cut with laser cutting? – Laser cutting can handle diverse materials, including delicate fabrics, rigid metals, wood, acrylic, and more. It offers precise and clean cuts, leaving smooth edges and minimal distortion.

Question: What are some unique applications of laser cutting? – Laser cutting has unique applications in the medical, architecture, and automotive industries. It is used to produce intricate components for medical devices, create architectural models, and manufacture vehicle components and parts.

Question: What factors should be considered when choosing a laser-cutting service? – Factors such as capabilities, expertise, and project suitability should be evaluated when choosing a laser cutting service. Consider the maximum material thickness, types of lasers used, equipment capacity, provider experience, and their ability to handle complex designs or patterns.