Aluminum alloy is a general term for alloys formed on the basis of aluminum. In life, due to factors such as different scenarios and applications, it is necessary to mix different elements into the primary aluminum to change the structure and performance of the original aluminum to obtain high strength or outstanding comprehensive performance. In general, the main elements contained in aluminum alloys are copper, silicon, magnesium, zinc, and manganese, and the minor elements include nickel, iron, titanium, chromium, lithium and so on.

Types of aluminum alloys

1. When it comes to purpose, it is mainly divided into two categories: cast aluminum alloy and deformed aluminum alloy.

Cast aluminum alloy: aluminum alloy suitable for filling a mold in a molten state to obtain a casting blank of a certain shape and size;

Wrought aluminum alloy: aluminum alloy with high strength, high specific strength and suitable for plastic forming.

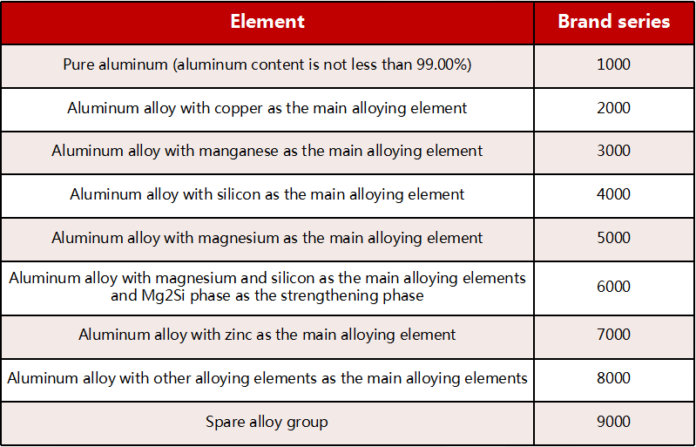

Grade classification

2. According to the manufactured products, it can be divided into industrial aluminum, aviation aluminum, civil aluminum, conductive aluminum, etc.

3. Divided into cooked aluminum and raw aluminum according to aluminum content.

4. According to the shape, it is divided into aluminum plate, aluminum ingot, aluminum wire, aluminum rod, aluminum cake, etc.

5. According to the source of production, it is divided into primary aluminum and secondary aluminum.

What are the strongest Aluminium Alloys

Aluminum alloy is the most widely used non-ferrous metal structural material in industry, and it has been widely used in aviation, aerospace, automobile, machinery manufacturing, marine aluminum alloy and chemical industry. Among these aluminum alloys, 7075 has the most outstanding comprehensive performance.

It is a high-quality, high-performance, and high-strength aluminum alloy. It is generally used for aircraft structural parts and other high-strength corrosion-resistant structural parts. It can also be used for other parts in the future. It is made of materials, so in terms of price, it is relatively more expensive than other aluminum alloys.

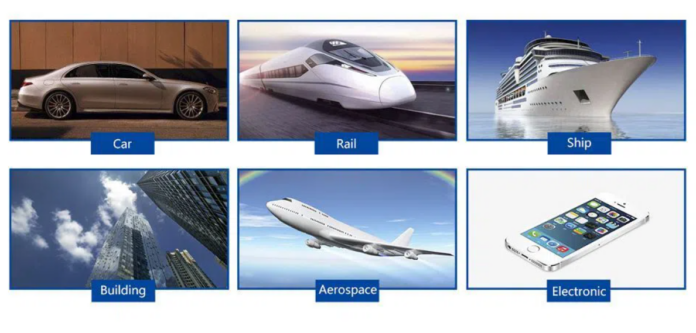

The application of Aluminium Alloy

Due to the excellent performance of aluminum alloy, it has a better performance in different industries, ranging from aerospace, shipbuilding, rail transportation, machinery manufacturing, etc., to daily necessities as small as lamps, food packaging, air-conditioning fins, Aluminum alloys exist in radiator components and so on. Because of the wide application of aluminum alloy, its industrial use is second only to steel.

Development prospect

China is a superpower with a population of 1.3 billion. As aluminum, which plays an important role in industry and daily life, its future development potential cannot be underestimated. In recent years, China has also continuously strengthened scientific research on aluminum.

In order to transform from relying on foreign technology and equipment to completely independent research and development, high-end aviation aluminum materials for medium and heavy plates have been used in large aircraft and military industries, and all aluminum materials for high-speed rail have been made domestically.

At the same time, environmental protection policies such as green environmental protection, energy saving and emission reduction have always been the basic policies that China has implemented. This year, China is also vigorously implementing policies such as “dual carbon”, electricity curtailment and production restriction.

As a traditional industrial industry, aluminum processing enterprises should improve The technology of aluminum processing products reduces pollutant emissions, reduces energy consumption, and improves the effective use of resources. It is developing in the direction of green manufacturing and helping China achieve “carbon peak and carbon neutrality” at an early date.