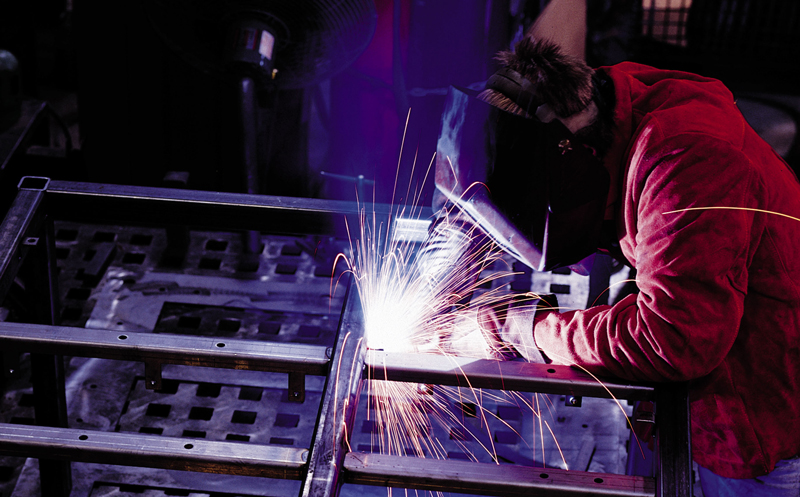

Quality welding means working without cracking, distortion, spraying, trimming and similar things. That is why it is important what skills and equipment you have. Skill is gained through experience, but equipment can significantly improve you even if you are a beginner.

1. Better welder

Given the profession in question, this subject is key to its success. These are high temperatures that heat the metal. In such a state, it melts and joins metal parts. It is shaped like a glue gun, because at one end there is an opening through which an electric flame comes out. You can also use it for MIG and TIG welding, but you need to have certain skills in order to do it on more complicated projects. That is why it is important to know the project work plan in advance before buying. It is also important to be aware of your skills and experience.

Additionally, understanding the specific materials involved in a project is crucial, as not all welding techniques are suited for every application, and using the wrong method can compromise the strength and durability of the final product.

For instance, for projects involving thermoplastic piping instead of metal, tools such as a Butt Welding Machine can be more beneficial, as they can create strong, seamless joints using controlled heat and pressure.

2. Shielding gas

Of course, protection comes first. That’s why everyone needs shielding gas to help you adequately protect yourself from electrodes during operation. Professionals know that it is very important to have these bottles on hand, and carbon dioxide and argon are most commonly used. In this way, it penetrates the metal best, but it also captures the space around it.

This is exactly the reason why a mixture of gases is used, because much better results are achieved than expected. In that case, you may mix carbon dioxide, helium and argon or something else. So, it all depends on the type of metal. Don’t forget about the amount of work you have, because you will have to provide a sufficient supply of gases in the warehouse. The new machines will show you the current level of gas in the unit and you will have a reserve if you run out of gas.

3. Angle grinder

This is one of the most important items used during welding. The purpose of the tool is to smooth the surface of metal projects as much as possible. This means the proper removal of paint, slag and other impurities. In addition, they are also used for cutting metal sheets. We have to mention that people also use a cut wheel for metal, a wire brush or a folding disc in order to achieve even greater precision.

4. Welding cart

If you work on projects often, you will definitely need this subject. This will make it much easier to operate the equipment as well as the sheet metal. This mobile solution helps you work on multiple projects in less time. For some, this trolley is also used for storing equipment, because it consists of a stand for installing welders. Of course, before you buy to use for these purposes, it is important to check the dimensions.

5. Welding helmet

If you care about improving your work in this professional field then you need to get the best equipment. A helmet is a key piece of equipment that protects you, but today you can choose models that offer more than that. So, look at welding.com.au for equipment that has different functions that will help you function better during the process. These models significantly improve and protect your eyesight, are more adaptable, have covers, smart functions, etc.

Conclusion:

Several factors affect the welding process such as labor, cleanliness, preparation, material, etc. However, this job involves their integration and that is why it is important to think about everything. For starters, get good equipment and everything will be easier.