Every designer and manufacturer knows how important every component is, and you need to pay attention to even the smallest ones if you want to provide the best for your customers. In addition to this, the right components will help you adhere to regulations and will provide additional safety for your devices. In this article, we are going to talk about power supply and converters, and how to choose the right type for your project. Continue reading if you want to find out what is the difference between isolated and non-isolated power converters.

Advantages and drawbacks of isolated converters

The first thing we are going to talk about is the benefits that come with this type of DC-DC supply, and why people choose to have this type of application. The main reason why you should go with them is the safety compliance, and these units are much safer especially when it comes to high voltage. The safety standards must be reviewed before choosing the right type of installation for your needs, and when it comes to this type of application, there are several categories that you can choose from when going with the isolated converters.

The functional method is the most simple one, and even though it is a good type of isolation, it still does not provide any protection against an electric shock. The reinforced type creates a barrier between two simple layers, and the supplementary one is just like the reinforced, but with one additional layer. Lastly, the basic one is similar to the functional ones, but it also provides protection against shock.

This type of supply is preferred because of its breaking of ground loop properties, and it is also good for floating outputs and level shifting. Note that when you choose this method, you will be able to avoid a lot of issues, and you will protect circuits that are sensitive to noise or easily damaged.

When it comes to drawbacks, you should know that there are not many that you should worry about. However, this type of power supply is more expensive than the non-isolated type, and the converters are much bigger in size. If space is not a problem for you, then you can choose them. You should also know that when it comes to performance and efficiency, the isolated converters are not as good as the non-isolated ones and you may experience some problems.

Nevertheless, if you are looking for something that is up to the highest safety standards, and if you need a connector that will provide additional protection when it comes to high voltage, you should go with this type of DC-DC supply.

Advantages and drawbacks of non-isolated

Now that you know more about the first model, let’s give you more information on what the benefits and disadvantages are of the non-isolated models.

The first reason why users choose to go with this type of connector is because of the price.

They are much less expensive than the other type, and they can be installed on many different devices. The fact that there is no transformer in these connectors means that they are going to be at a lower price and since there is no need for isolation, this subtracts from the overall cost of manufacturing as well.

As we mentioned before, there are no barriers or convertors in these models, so they are much smaller and slimmer in size. This means that they can easily be installed on small devices, and you don’t have to worry about them taking too much space.

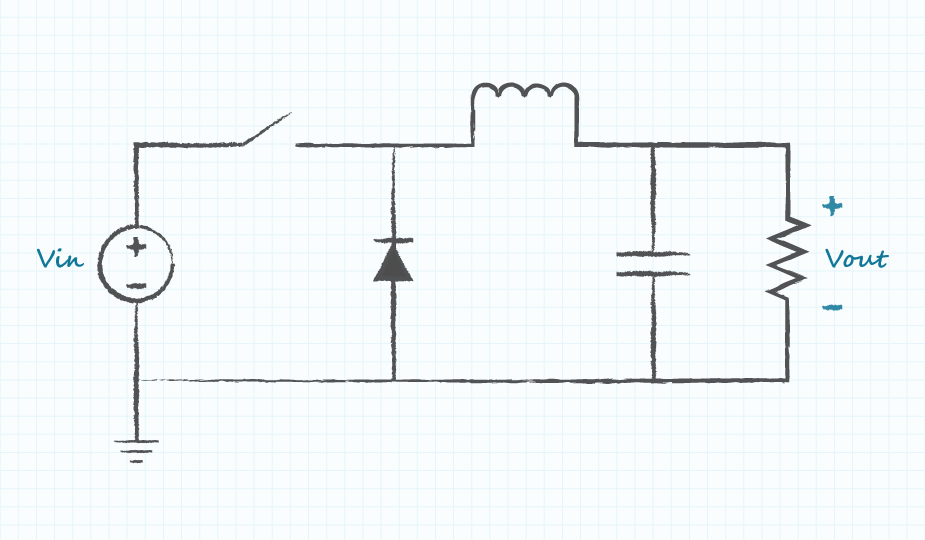

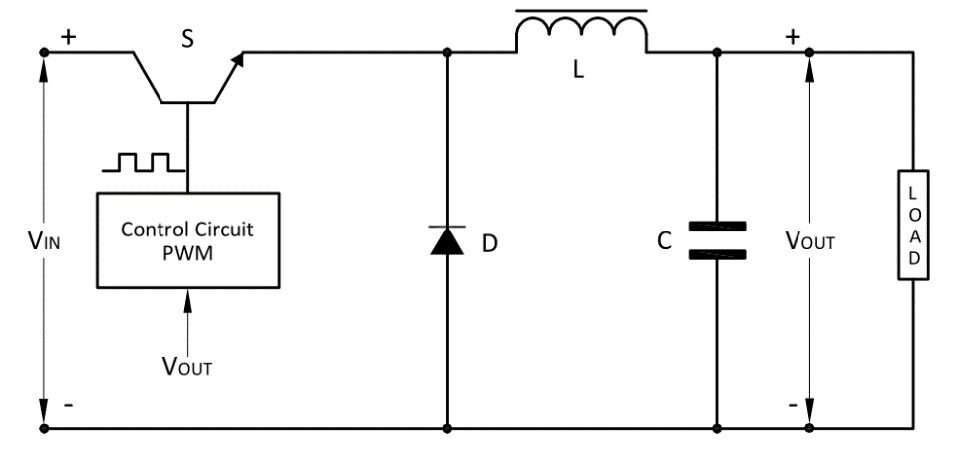

Lastly, these models are much more efficient, they can be easily controlled, and they can be placed near the load, and with that, they reduce any effects that might come from the transmission line.

On websites like szysdwps.com, you can see that these connectors are waterproof, they have almost 95 percent of conversion efficiency, they provide protection from overheating and overloading, and they are also extremely thin.

When it comes to drawbacks, there are not many, however, this is not a type of power supply that you should use if you want increased protection. Since there is no barrier between the layers of this type, it is not recommended for devices that will be exposed to high-voltage current. The isolation is not present here, and if they are installed in industry-specific devices, they can pose a serious hazard to safety. They are best used for simple devices and places where there is no need for isolation barriers. To avoid any safety concerns, this type of supply is usually downstream from convertors that provide a barrier and this helps a lot when it comes to providing additional support.

Main differences

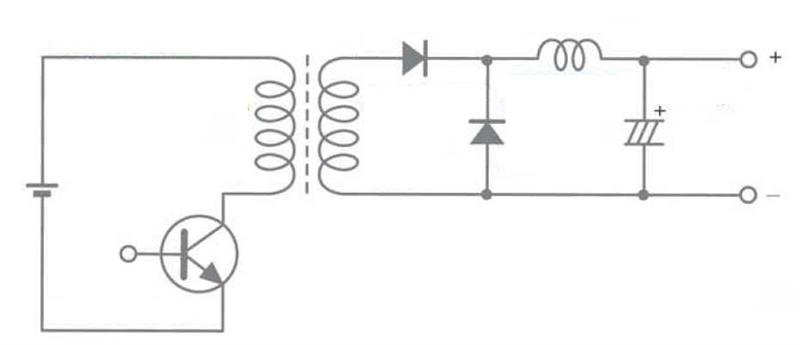

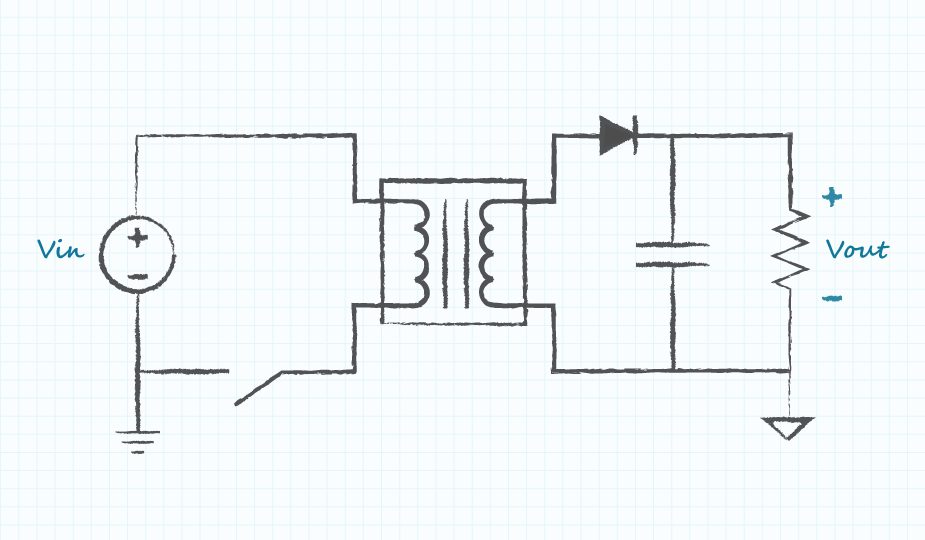

As you can see, even though these methods are similar, there are still some differences between them. The isolated supplies are great for providing a clear barrier when it comes to high voltage, and with that, they increase safety. On the other hand, they are a lot larger because a transformer needs to be installed. When it comes to applications, you should know that this model is mostly used in medical devices or places where there needs to be a strong barrier between the input and the output. In addition to this, they are implemented in industry-specific devices that use higher voltage.

The non-insolated models are much more efficient and smaller than the other type, but since there is no barrier between the input and the output, they can be more hazardous than the other type of DC-DC supply. These units are mostly preferred for simple devices and models, and they are also chosen when the barrier is not vital. They are mostly installed in smaller and simpler devices like sensors, appliances, and lighting fixtures.

These are some of the differences when it comes to different conversion models and connectors. If you are not sure which one is the right type for your project, the best thing you can do is contact a professional and get their expert opinion. Know that there are a lot of different subtypes and models that you can choose from, and the overall quality, cost, and efficiency will depend on the model as well.