A ball spline system is needed when rotational and linear movements are required. Previously, it was not possible to go in both motions. However, the ball spline system has provided ease. This system has less friction and also less binding tendency. Thus, you get high efficiency with fewer efforts.

Ball spline system

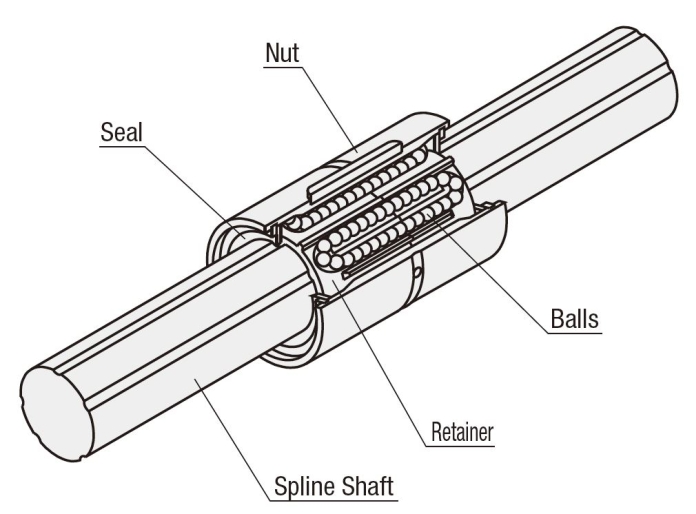

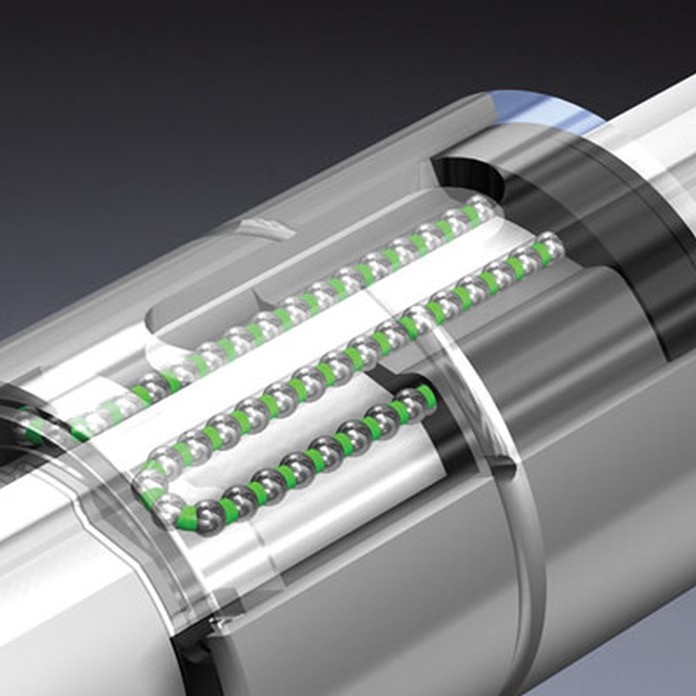

A lot of typical motion applications now use ball splines, because of the friction-less movement they offer. It consists of a spline (inner race), an outer race and a mating linear bearing. The inner race is made from alloy steel, which is induction heat treated at 56 to 60 Rc (Rockwell C hardness). Moreover, some other splines have a ball groove cross-section of the gothic-arch type that increases its service life. Furthermore, it also offers a smooth operation and low rotating lash. Then there is the outer race, which consists of bearings of hardened steel at 58 to 60 Rc. Furthermore, there are recirculating bearing balls that reduce any wear through friction. Thus, it allows you to have unlimited travel with the least maintenance. In addition to this, the outer race also has various active circuits where 3 to 6 are typical. Thus, with the use of a ball spline system, you will have easy movement while operations. So if you are looking for a ball spline go to tuli-shop.com. You will get all the related products like ball spline shafts, SLT bushing and SLF bushing too.

Applications of ball spline

Ball spline has extensive use throughout industrial operations. But it is not limited to that only. They are also used in;

- Honing machines

- Medical

- Robotics

- Automation and packaging equipment

- Oil and gas exploration

- Water exploration

Modifications of inner and outer races

You might not know this but you can modify both inner and outer races. So if you have some specific demands, you can ask for any modifications according to your use. You can have setscrew or keyways holes for outer races. Likewise, you can have threaded ends or journals for the inner races. You can machine them all if you need them. Likewise, if you need extra-smooth motion, a longer service life, close tolerance, precision ground ball splines offer it all. Furthermore, the hollow shafts reduce the weight of the system but it will make it a bit lose. Thus, you will have a loss in stiffness.

Service life

As you will get efficient movement, you will want a longer service life and you get that here. If you get the right size, you will get the service life at an average torque. If you use the highest torque, you need some extra life depending upon the length of travel. Therefore, it is quite important that you pay attention to the use. This will allow you to get the right size of ball splines.

Critical speed

Before getting the ball spline system, you have to verify the critical speed of the shaft. It also depends upon your use. The use of medical equipment is different from robotics and therefore, the speed varies. The motion in industrial use varies from that of medical practices. Critical speed is the maximum speed at which the ball splines will move effortlessly.

If you increase the motion beyond the critical speed, this will result in causing vibrations and natural harmonics. And you won’t want that. Furthermore, this critical speed varies with the load-carrying capacity, diameter, rotary speed, the distance between supports and the end fixity or type of bearing support that you use. Thus, before getting the system, you need to pay attention to these things and get the right equipment.

The support systems are different because of the varying use. Therefore, you will get 4 major categories in the support system. These include;

- The one with one free end and one fixed end

- Where both ends are simply supported

- The type where one end is simply supported and the other one is fixed

- The type where both ends are fixed

Friction-less movement

The most important use of the ball bearing system is friction-less movement. These are efficient and offer a rolling motion. Thus, the service life is high. In a simple linear motion system, the friction is high and that wears down the equipment. However, with friction-less movement, you will be able to use the equipment for a longer time.

Takes less space

Traditional linear motion systems are used in dual-shaft configurations. They ride on the shafts and thus, prevent rotating movement in bearings. On the other hand, the ball spline system has a single shaft configuration and thus, they take less space. This means that they will have a small footprint and also less weight. Furthermore, their assembly will also be easy and so does their alignment.

Dual motion in one system

Linear ball spline systems offer a dual motion movement. This includes linear movement and a rotary movement. Thus, they are the best solution for Z-theta axes. And this is also the reason for their wide use in robotics and the industrial sector. This dual movement property of this system makes it suitable for CNC machines where they act as automatic tool changers. Likewise, pick and place machines also use them. Because they allow the picking of things from one conveyer and place it on the other.

The amount of twist

It is an angular movement per a linear foot of spline. The amount of twist in the system also varies with its size. The worst-case twist values include; 1.25-degree twist per feet in 15 minutes with 3/8 ball circle diameter. Likewise, a twist of 0.5 degrees per foot in 30 minutes with 1 ball circle diameter. And with 1.7 degrees twist per feet in 10 minutes with 2.5 to 3 ball circle diameter.