The idea of a part being cut, shaped, measured, and checked to the width of a human hair can feel almost abstract until you see it happening on a CNC floor. The sound is steady. The movement is exact. The operator barely looks up because the machine is speaking in thousandths.

Precision manufacturing has become one of the strongest areas of industrial growth in India, and that progress did not arrive overnight. It came through steady investment in skills, tooling, metrology, and process control.

High precision CNC machining may look like a quiet field to an outsider. In reality, it is a demanding corner of manufacturing where repeatability is everything, and customers often bring parts that cannot tolerate even a minor deviation.

Aerospace, medical devices, automotive, robotics, energy, custom machinery, you name it, all rely on suppliers who can keep tolerances tight and maintain quality with a kind of calm predictability.

Here’s a clear look at how Indian manufacturers achieve that level of quality, the processes behind it, and the capabilities that shape the sector today.

The Foundation of Precision Manufacturing in India

Precision grew through a mix of factors that kept raising expectations on the shop floor. Better access to CNC machines with multi-axis control.

Stronger training programs. Rising customer requirements across export markets. As a result, many facilities now run machining centers that rival international competitors.

Companies like ROBOCON show how steady investment in tooling and process control has shaped India’s precision manufacturing base.

The Core Advantages India Brings to High-Precision Work

A few patterns show up repeatedly when looking into suppliers that perform well.

- Skilled machinists who can handle CAD and CAM workflows with ease

- Automated tool measurement and compensation systems that keep cutting accurately

- Tight process documentation, often modeled after ISO 9001, IATF 16949, or AS9100 requirements

- Growing investments in metrology, from CMMs to surface roughness testers

- Lean manufacturing habits that reduce variation and improve part consistency

Manufacturers who combine those elements usually deliver reliable parts across mid and large production runs.

What Precision Actually Means in CNC Machining

People often picture tight tolerances as some abstract number on a drawing. In practice, it shapes everything from how the part is fixtured to the sequence of operations.

Tolerance Ranges You Commonly See

High precision CNC suppliers in India frequently work with tolerances such as:

| Feature Type | Typical Tolerance |

| Hole diameter | ±0.005 mm to ±0.02 mm |

| Shaft features | ±0.005 mm |

| Flatness | 0.01 mm to 0.05 mm |

| Surface roughness | Ra 0.8 to Ra 1.6 µm for standard precision |

The numbers vary slightly depending on material, part geometry, tool wear rate, and the cutting environment. A long, slender shaft reacts differently than a compact block. Aluminum behaves differently from hardened steel. Precision is always tied to context.

Material Choices That Shape the Process

Indian facilities machine a wide spectrum of materials. Some of the most common include:

- Stainless steels such as 304, 316, 410, and 420

- Aluminum grades like 6061, 6082, and 7075

- Mild steel and alloy steels

- Brass, copper, and bronze

- Engineering plastics such as PEEK, Delrin, and Nylon

Every material brings its own playbook. Stainless steel generates heat. Aluminum encourages faster speeds but punishes poor chip control. Plastics demand keen awareness of tool sharpness. Precision machining only works when the machinist respects those quirks.

Key CNC Processes Behind High Precision Parts

A precision part rarely comes from a single operation. It usually moves through a sequence that trims, shapes, drills, bores, finishes, and measures.

CNC Turning

Turning handles cylindrical features. Many Indian facilities run turning centers with:

- Live tooling for secondary operations

- Sub spindles for improved cycle efficiency

- Bar feeders for continuous production

- In-process probes that correct tool offsets on the fly

Precision turning is commonly used for shafts, pins, bushings, and threaded components. Shops often apply hard turning for materials up to around 60 HRC to reduce the need for secondary grinding.

CNC Milling

Milling shapes prismatic features, pockets, slots, and contours. A typical workflow includes:

- 3-axis machining for general shapes

- 4-axis for improved feature access

- 5-axis for complex contours and reduced setups

Precision milling depends heavily on fixturing. A rigid fixture lets the machine cut consistently without micro movement. Shops often use vacuum fixtures for thin plates, modular clamps for varied parts, and zero-point systems for fast changeover.

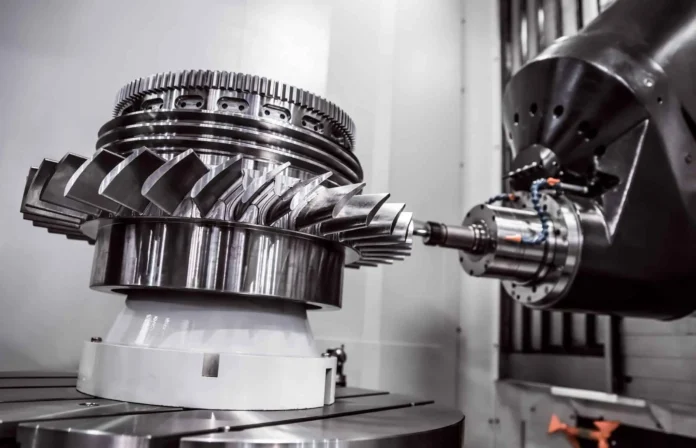

Multi Axis Machining

Multi-axis capability has grown rapidly in India. It reduces human handling and protects accuracy by performing more features in one setup.

Jobs that benefit from multi-axis include:

- Aerospace housings

- Robotic arm components

- Medical implants

- Turbine-related parts

Fewer setups mean fewer chances for misalignment.

Surface Finishing and Post-Processing

Precision parts often require finishing steps:

- Grinding for ultra-tight size control

- Polishing for medical and cosmetic applications

- Anodizing or plating for corrosion protection

- Passivation for stainless steel

- Shot blasting for uniform surface texture

Each finish affects not only appearance but long-term performance.

How Accuracy Is Maintained on the Shop Floor

Anyone who has watched a machinist adjust a tool offset can spot the blend of experience and measurement that keeps everything in tolerance.

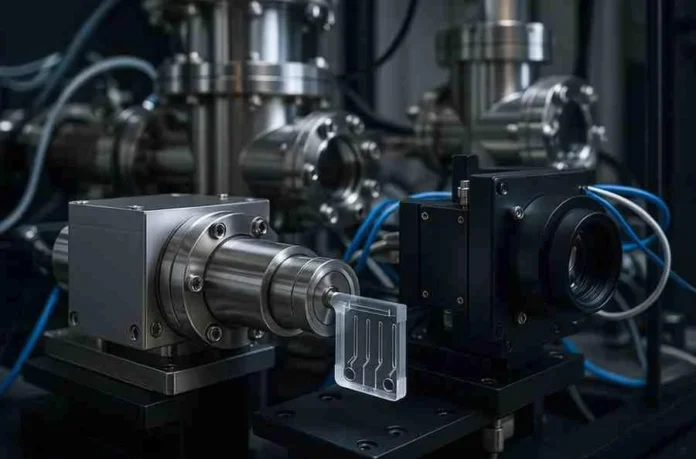

The Metrology Tools That Matter Most

Quality control teams rely on:

- Coordinate measuring machines for dimensional checks

- Height gauges for quick inspection

- Pin gauges and bore gauges for internal features

- Micrometers and calipers for basic checks

- Profilometers for surface roughness evaluation

CMMs have become especially important for export manufacturing. A well-programmed CMM report builds trust quickly.

Process Control Habits That Drive Precision

A few recurring habits elevate the accuracy level inside Indian machining shops.

- Tool presetters that measure tool length and diameter before the tool enters the machine

- Regular calibration of machines to match thermal and mechanical drift

- Controlled cutting parameters that manage heat buildup

- Batch-wise inspection rather than end-of-run inspection

- Clear traceability for material batches and measurement data

It may look simple on paper. In practice, those habits require steady discipline.

CNC Machining Capabilities Commonly Offered in India

A customer looking for precision parts often checks capability lists before shortlisting a supplier. Most reliable shops in India display a range like the one below.

Capabilities Snapshot

| Capability | Typical Range in Indian Shops |

| Turning diameter | 5 mm to 500 mm |

| Milling envelope | 500 mm to 2000 mm, depending on the machine |

| 5-axis machining | Available in many mid to large-sized facilities |

| Batch size | From 10 pieces to tens of thousands |

| Material scope | Aluminum, steel, stainless, brass, plastics |

| Surface finish | Ra 0.8 µm achievable on many machines |

Some suppliers specialize in small, intricate parts. Others focus on heavy industrial components for energy and infrastructure. The field is diverse, and the scale varies widely.

Industries That Rely Most on Indian Precision CNC Parts

The demand is not limited to domestic customers. Many suppliers build parts for global firms, often through long-term contracts.

Aerospace and Defense

CNC parts for aerospace require traceability and strict quality gates. Many Indian manufacturers hold certifications that support export to aerospace customers.

Common aerospace parts include:

- Housings

- Brackets

- Bushings

- Engine components within controlled tolerances

Automotive and EV

India’s automotive ecosystem is one of the strongest in Asia. Precision machining plays a central role in:

- Transmission components

- Fuel system parts

- EV motor housings

- Suspension and steering parts

Cycle time and repeatability matter greatly in this segment.

Medical Devices

Medical machining leans on stainless steel, titanium, and engineering plastics. The work demands polished surfaces, burr free edges, and consistent sizing.

Industrial Automation and Robotics

Robotics companies require parts that support linear motion, rotation, and structural stability. Machined aluminum and steel parts fill that gap reliably.

What Sets High-Performing CNC Shops Apart

A walk through any machining floor reveals differences quickly. You can often spot the high performers by the way the shop feels.

- Machines are clean, aligned, and inspected regularly

- Tools are labeled and stored with care

- Cutters show signs of steady replacement rather than last-minute substitutions

- Material racks follow clear organization

- Operators keep measurements logged rather than relying on memory

Those habits speak loudly to customers who need a shop that can deliver consistent accuracy across long production cycles.

Tips for Buyers Sourcing CNC-Machined Parts in India

A precise part starts with a precise supplier relationship. Many buyers have developed simple habits that help them source effectively.

Share Detailed Drawings and Tolerance Priorities

Manufacturers appreciate clarity. Drawings with complete GD&T symbols, surface requirements, and material specifications allow for smoother quotations and fewer surprises during machining.

Ask for Sample Reports

CMM reports, process sheets, and tool lists help you verify that the supplier can handle your part. A good shop is usually proud to show its inspection routine.

Consider Long-Term Value Rather Than Only Cost

CNC machining comes with variation if corners are cut on the tooling or inspection. A slightly higher per-part price often means fewer rejections and more predictable timelines.

Build in Feedback Loops

When suppliers receive dimensional feedback from your incoming inspection team, they can make early adjustments that keep future batches aligned.

The Direction India’s Precision CNC Sector Is Moving Toward

Growth is steady. More shops invest in automation, pallet systems, and multi-spindle machines. Metrology labs continue to expand. Training programs for machinists grow stronger each year. As customer expectations rise, the industry pushes quality further.

There is a quiet confidence inside many Indian CNC facilities. The teams know their craft. They know their machines. They know how to keep a tolerance steady across thousands of cuts. That kind of reliability earns trust, and the market rewards it quickly.

Summary

Precision machining lives in the smallest details, and Indian manufacturers have spent years refining those details until they have become dependable habits. Skilled teams, strong process control, modern machines, and expanding metrology capabilities have positioned India as a solid source for high-accuracy CNC parts across global industries.

Customers who work with Indian suppliers often stay for the long term because the parts arrive as promised, the communication stays clear, and the quality holds up across tight deadlines. The field continues to grow, and the momentum behind it feels steady and grounded.