In today’s fast-paced manufacturing and distribution environment, companies are increasingly turning to packaging system integration to streamline operations, reduce errors, and improve efficiency.

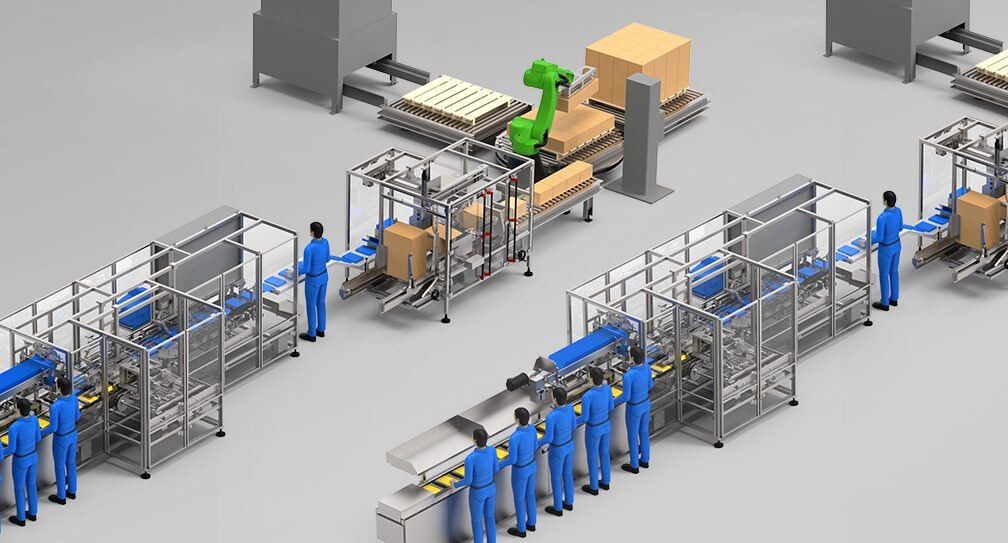

Packaging system integration involves connecting various machines, software, and production processes into a cohesive, automated workflow.

While the benefits are clear—higher productivity, better data tracking, and reduced labor costs—successful integration is not without its challenges.

Understanding these challenges is essential for businesses planning to implement integrated packaging solutions.

1. Compatibility of Existing Equipment

One of the first hurdles in packaging system integration is ensuring that existing machinery can communicate effectively with new automated systems.

Many facilities operate a mix of legacy equipment and modern automation. Integrating these systems often requires careful planning, custom interfaces, or middleware solutions to ensure seamless communication.

Without proper compatibility, the risk of production delays or errors increases.

2. Software and Data Synchronization

Packaging system integration relies heavily on software that controls machinery, monitors performance, and tracks production data.

Integrating multiple software platforms can be complex, especially when different machines use proprietary systems.

Data synchronization issues can result in inaccurate inventory tracking, mislabeled products, or production bottlenecks. A thorough audit of software compatibility and clear data mapping strategies are critical steps in overcoming this challenge.

3. Workflow and Process Standardization

Even with compatible machinery and software, successful integration requires standardized workflows. Each packaging line must operate with consistent timing, speed, and quality parameters.

Disparities in workflow across different machines or production stages can cause misalignment, errors, and increased downtime. Standardizing processes before integration simplifies system setup and ensures smoother operation.

4. Employee Training and Change Management

Transitioning from manual or semi-automated processes to fully integrated packaging systems often demands a shift in workforce skills.

Operators and supervisors must understand how to interact with new machinery, troubleshoot issues, and monitor system performance.

Comprehensive training programs and clear documentation are essential for preventing mistakes and maximizing the benefits of automation.

5. Maintenance and Scalability

Integrated packaging systems require regular maintenance to ensure ongoing performance. Maintenance schedules must account for all interconnected machines and software updates.

Additionally, businesses should consider future scalability during integration planning.

A well-designed system allows for additional machines or upgraded components to be added without disrupting operations.

Conclusion

While packaging system integration presents challenges, understanding and addressing these issues can make the implementation process much smoother.

From equipment compatibility to employee training, careful planning and strategic execution are key to achieving a fully integrated packaging operation.

When done correctly, integrated systems not only improve efficiency but also enhance accuracy, reduce waste, and provide valuable data insights for continuous process improvement.

For manufacturers seeking a competitive edge, embracing packaging system integration is not just an option—it’s a step toward more efficient, adaptable, and future-ready operations.