For most construction sites, a 50-gallon, DOT-approved, baffle-equipped portable tank with a 12V pump (≈15 GPM), off-road mobility, and one-person operation delivers the best uptime per dollar.

It solves the last-mile problem (truck → machine), works on debris and grades, and can be left on site so operators refuel without waiting.

Why Construction Needs a Purpose-Built Portable Tank

@smartassproducts Where do you take your Fuel Mule? Darn near anywhere you want to. 50 gallons of fuel across any reasonable terrain. Gas up that boat, plane, farm or construction equipment! LET’S GOOOO!! @Sean Sliv Silveira @Jett Lambert @Matt Manzari @thomasherman #fuelmule #smartassproducts ♬ original sound – smartassproducts

Construction refueling isn’t like topping off a vehicle in a paved yard. Crews work around mud, gravel, rebar, steep grades, and tight access paths that trucks simply can’t reach. A portable tank on a construction site must handle impact, vibration, and incline without spilling or slowing down operations.

The challenge isn’t just storage, it’s what’s known as the “last-mile” fuel problem: getting fuel from the truck or central tank to the actual machine efficiently and safely.

That last stretch is where most systems fail. Traditional jugs are cheap but backbreaking. Standard gas caddies roll fine in a warehouse but get stuck on gravel.

Permanently mounted transfer tanks provide plenty of volume but force you to give up valuable bed space.

What the industry truly needs is a mobile solution that brings speed, control, and terrain capability together in one package.

Comparing Common Fueling Options

| Type | Capacity | Terrain & Mobility | Pumping Speed | Truck Bed Impact | Jobsite Suitability |

| 5-gallon jugs | 5 gal each | Carried by hand, no wheels | Manual pour, frequent spills | None | Emergency use only |

| Traditional gas caddy | 14–30 gal | Small hard wheels, poor traction | Hand crank or slow pump | None | Flat surfaces only |

| Bed-mounted transfer tank | 50–100 gal | Depends on truck access | 10–15 GPM | Permanent bed loss | Capacity yes, flexibility no |

| Modern motorized gas caddy | Around 50 gal | Off-road tires, brakes, compact | 15 GPM electric, auto shutoff | Removable | Ideal for jobsites |

This comparison shows how most legacy fueling methods fall short when you leave the pavement. Even the best steel transfer tank is only useful if the truck can reach the machine, and that’s rarely the case in real-world conditions.

The Modern Jobsite Solution

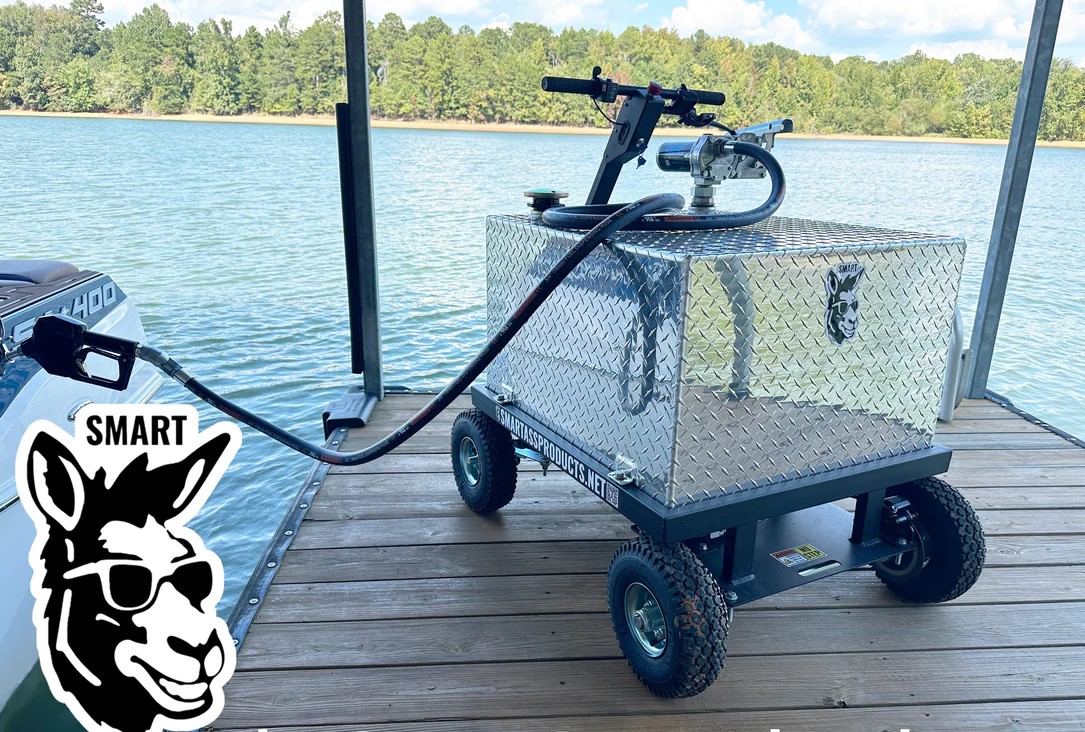

A new generation of portable fuel systems has changed how professionals refuel equipment. A gas caddy merges the portability of a wheeled caddy with the capability of a small fuel truck. It carries about 50 gallons, enough to refuel multiple machines in one pass, and delivers fuel at up to 15 gallons per minute with an electric pump and auto-shutoff nozzle.

Unlike standard caddies, these systems feature internal baffles to prevent slosh, hydraulic brakes for stability on slopes, and off-road tires that roll easily across gravel, grass, or compacted soil. Because the tank is DOT-approved, it’s legal for road transport and safe to move between sites. It’s designed for one-person operation, which means your foreman or site worker can handle fueling without assistance or heavy lifting.

Why It Matters on the Job

A properly built portable tank transforms daily workflow. Instead of sending the truck back and forth from a bulk tank or relying on jugs, the foreman can drop a mobile unit with the crew in the morning. Throughout the day, operators refuel their equipment on-site in minutes, rather than stopping work for half an hour each time. That change alone can save one to two labor hours per machine per shift, a measurable boost to productivity.

Safety improves, too. Auto-shutoff nozzles prevent overfilling, baffles control weight shifts on ramps, and vented caps maintain safe internal pressure. The ability to leave the tank on site also frees up truck space, allowing supervisors to haul materials or tools instead of being tied up with fuel delivery.

The Bottom Line

The best portable tank for construction isn’t the cheapest one; it’s the one that keeps your team working safely, independently, and efficiently. For most operations, that means a motorized, 50-gallon, off-road-capable unit that can be moved by one person and fueled electrically at high speed.

It’s the practical answer to the last-mile problem: getting fuel directly to where the work happens.

With the right portable tank, fueling becomes a quick routine instead of a production bottleneck, and that’s how jobs stay on schedule and under budget.