You might already know that pharmaceutical companies require proper rules of instruction and regulations to ensure that the company can work properly. Many companies often do not live up to their objectives because of the lack of management and coordination.

Out of all the industries that professional packaging suppliers and logistics companies serve, the pharmaceutical industry mandates unique needs and regulations. Its products are among the most delicate and strictly regulated globally, and with good reason. Further, we will talk about some of the dos and don’ts that should be kept in mind by the companies that are planning to open an industry of pharmaceutical products.

Some Do’s And Don’ts For Maintaining A Pharmaceutical Products Industry:

Let’s check out some of the dos and don’ts that the industries should never neglect to ensure that all the objectives are maintained and the smooth functioning of the pharmaceutical industry.

Always Use Cleanroom Pallets:

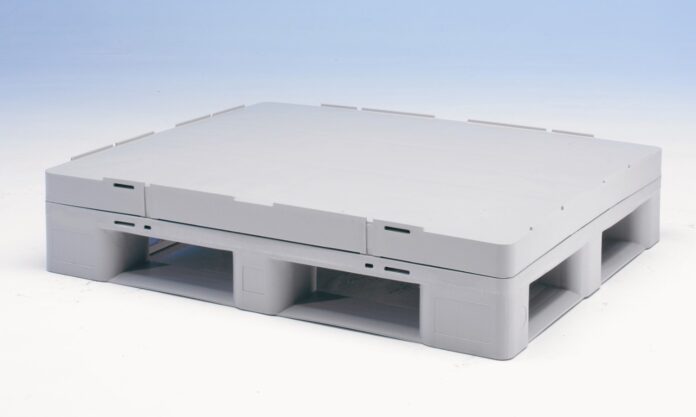

Pallets made specifically for the pharmaceutical and food sectors are known as cleanroom pallets. They have a straightforward layout without sharp edges or confined places where dust, liquids, and grime can amass over time. Professionals recommend them, and it ensures that the quality of the product can be maintained.

These durable, sanitary pallets can be used securely for the whole voyage of pharmaceutical products from the manufacturing line to the pharmacy shelves.

In controlled environments where laminar flow equipment is used to maintain particle-free air circulation, such pallets can further support contamination control by minimizing debris and surface buildup.

They are also simple to clean and disinfect. They play a significant role in maintaining hygiene and sanitation.

Manufacture Product With Right Machinery:

Always use good quality machinery to ensure that all the products can be manufactured easily. If you are planning to open a factory, it is essential to approach the right manufacturers. You can use a liquid capsule filling machine from good suppliers that can ensure you have efficient packaging.

Choosing the right machinery is only part of producing a high-quality product; attention to precision, efficiency, and durability throughout the production line is equally important. Ensuring all components work seamlessly together helps maintain consistency and reliability in the final output. For example, the role of high-performance connectors, like the best flexible coupling, precision-milled shafts, and stainless steel mixing paddles, can be crucial in keeping mixers and other equipment operating smoothly and efficiently.

Keep in mind that you will need to have the right PPE when manufacturing as you do not want to contaminate the product, nor hurt yourself as you use the machinery. Wearing protective gloves, masks and Z87 prescription safety glasses (or similar) will keep you safe and make sure everything runs smoothly.

Don’t Keep Pharmaceutical Products In Fragile And Inadequate Packaging:

Pharmaceuticals should never be packaged in cardboard boxes, not even for the brief van ride from a nearby storage facility to the pharmacy. When the van hits a pothole in the road, glass vials may break. Due to the fragility and ease of tearing cardboard, other products could spill over the unclean truck floor. Storage of medical products should be kept in mind so that it can ensure that it does not break easily.

When Transporting Pharmaceutical Products, Use Specialized Distribution Totes:

Nestable boxes with lids for the pharmaceutical business were specially created and produced for these delicate products. They provide the best protection against shocks, vibrations, dust, spills, and other hazards so that pharmaceutical supplies reach their destination in perfect condition. There are many different manufacturers in the market that ensure how a particular product should be stored and how to maintain its sanitation of it.

Utilizing Data Properly:

Companies can keep up with compliance changes and enhance performance with real-time data access. An organization can successfully reduce the effects of non-compliance by doing this. The data should be maintained properly, as the administration of the industry might get disrupted. Unfortunately, out-of-date technology is one of the main reasons why organizations can’t make use of the data that is available.

It can be difficult to compile data from legacy systems. The majority of old systems offer inaccurate data, and integrating fresh data is a challenging procedure. It further prevents pharmaceutical corporations from reporting compliance.

Conclusion

This article will work for you as a guide and help you know more about the pharmaceutical industry and what all things should be kept in mind when you are establishing the industry.

This way, it can be easy for you to ensure a successful industry.