An electrical discharge machine or as it is commonly referred to as ‘EDM’ is a non-conventional method for removing a piece of material from a specific surface by utilizing thermic energy. Similar to laser cutting tech, EDM doesn’t require any mechanical force for completing the removal process. But, what exactly does it do? Luckily for all individuals that are wondering the same thing, here is what you should know about these devices:

EDM: Explained

As we mentioned, an electrical discharge machine is a production process that’ll accurately separate excess materials from conductive surfaces by using an electrode, which means that it’ll leave a negative imprint on the surface. Since there is a gap between the wire and the piece that is being worked on, a discharge happens that separates the material by one of two methods – either vaporizing or melting. Because of this, the piece has to be placed in a dielectric liquid.

The concept behind this process is that it’ll control electrical sparks that transmit imprints on the element and throughout the process, the wire and workpiece never touch one another. According to the experts from oscaredm.com, the amount of substance removed with a single spark of the electrode is relatively small, however, since the discharge happens approximately 100.000 times per second, this process can actually save a lot of time.

As the electrode moves closer to the piece, the electric field known as the ‘spark gap’ increases until it reaches a breaking point. At this moment, the fluid – in which the discharge occurs – is not conductive, thus, the discharge can heat the material quickly, and at the same time, it melts excess materials off. The material is then removed by the dielectric fluid, which is also used for cooling down the machine and controlling the sparks when and if needed.

There Are 3 Machine Types

Before we conclude this article, it’s worth mentioning that there are 3 types of such machines, including:

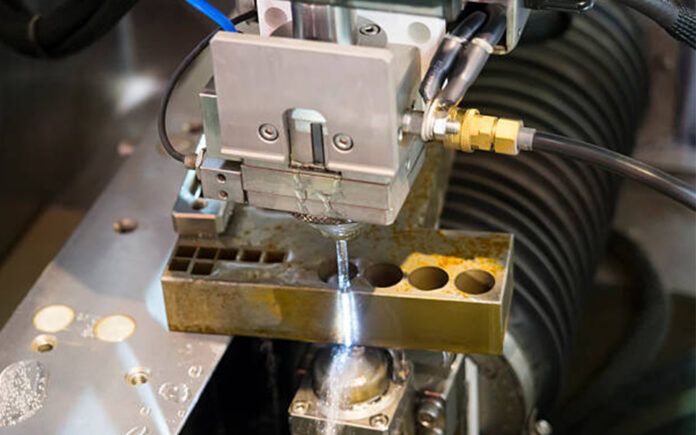

1. Die Sinking

Is a suitable option when there are complex cavities that have to be worked on. A reverse-shaped graphite wire is utilized for the process and the material is also placed in a dielectric liquid. The die is then slowly moved towards the working surface until the breaking point which melts or vaporizes the exterior. The excess is extracted from the component, which is what cuts the expected shape.

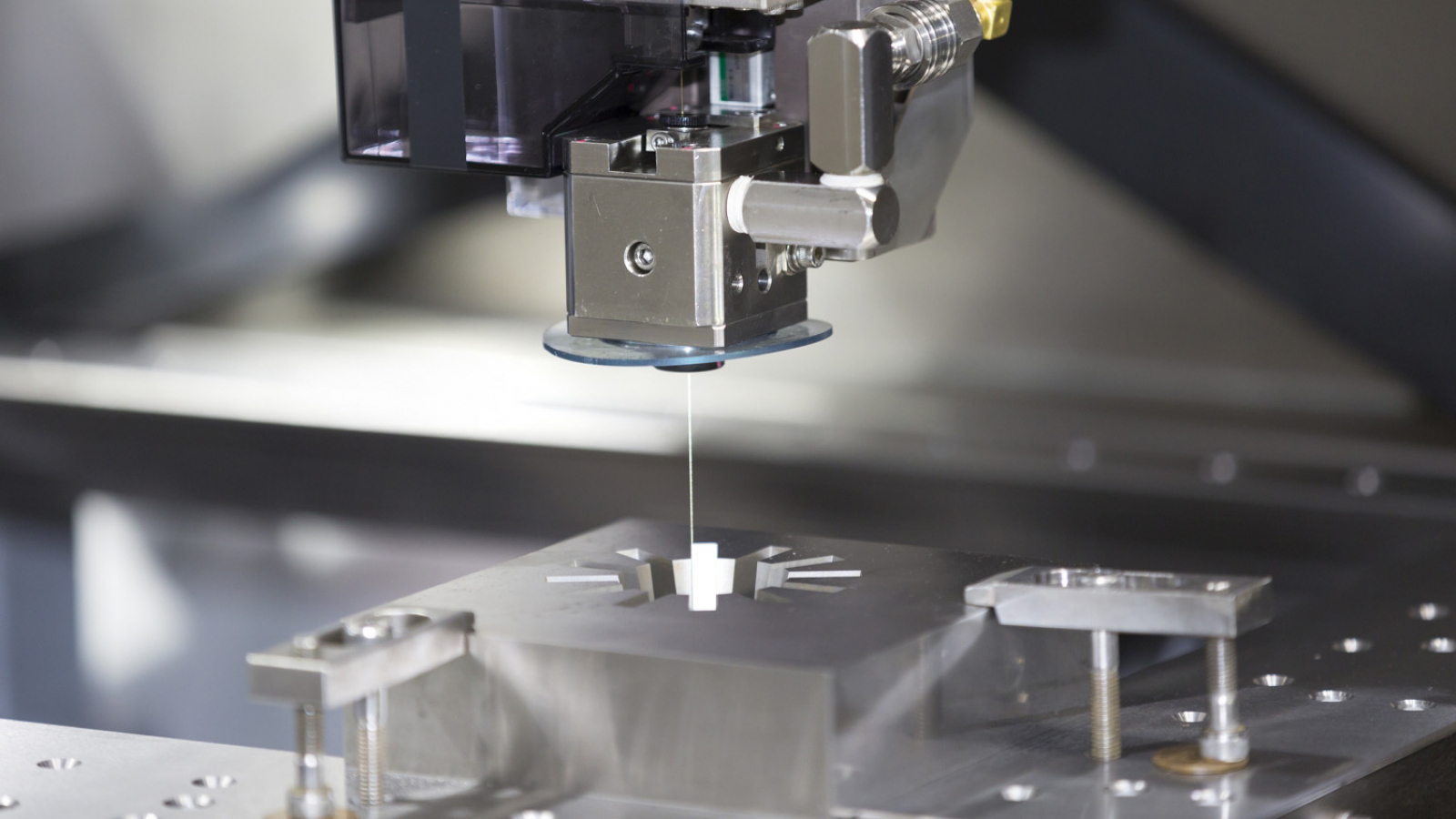

2. Wire

Commonly known as wire corrosion is utilized for constructing extrusion dies. It’ll cut as the aforementioned device, but, the die is replaced with a wire that has been charged with electricity. This method is capable of making 2D cuts in a 3D component. Since the wire burns throughout the process, it has to be automatically replaced – something that’ll guarantee that the cuts are precise.

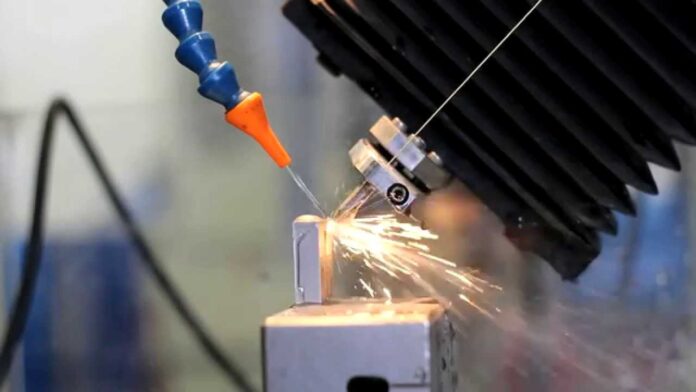

3. Hole Drilling

Last on our list is a hole-drilling machine, but when compared to standard hole drilling schemes, this one will have increased precision since the EDM device can cut tiny and deep holes. The cuts are made with a circular electrode that keeps pulsating and that goes deep into the surface in order for a substance to be removed. This cutting technique has been quite important in the improvements of huge-temperature turbine blades since it enables cooling of the channels inside of the blades.

Conclusion

Although a lot of people think that it’s quite difficult to understand the processes behind electrical discharge machines, it isn’t. And, once you understand the main concept behind this machining type, everything else will be relatively easy for you to comprehend. Since you now know what these machines are and what they can do, you could easily determine what you might have to use for completing one of your projects.