The injection molding industry is growing at a fast rate in the past few years. Do you know what the main reason behind it is? Well, it is because innovations are taking place every day. If you don’t know anything about them, you don’t have to worry. In this article, we will share some of the most popular innovations in detail.

Plastic mold technology has made the manufacturing of various products easier. Many businesses use this technology for a smooth manufacturing process. You might already know that advancements in technology are paving our way to significant achievements. So, we can expect more unique things in the future.

What are the latest innovations in the injection molding industry?

1. Micro Injection Molding

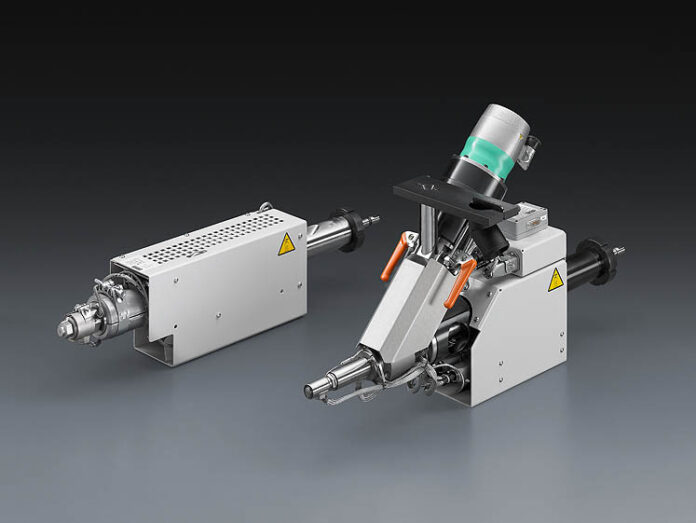

As the term suggests, it is a type of injection molding that produces micron molds. It was not possible in earlier times, but improvements in technology helped a lot. The demand for micro molding is increasing as they are essential to manufacturing various valuable products. The tools used in the medical field are highly dependable on these micro molds.

It has become more convenient for the molding manufacturer to handle all these things. There is no possibility of defects from the advanced machines and equipment. However, one needs to have sufficient knowledge regarding the same.

2. Remote monitoring is possible through an app

You might be surprised to know that remote monitoring is now done through an application. Everything about the production process would be available to the manufacturer with the help of this app. So, in this way, one can prevent mistakes in the initial stages.

3. Improvements in automation

Automation might not seem like an innovation, but it actually is. People often forget the importance of automation as they think it is common. It is essential to look at advanced technology like the use of robots.

Now, intelligent robots are available for people to manage all the manufacturing tasks efficiently and effectively. Due to this, the demand for human operators has been reduced to some extent. It will continue to deteriorate in the future as well. We cannot say it is a good thing or a bad thing. Still, it is suitable for the injection molding industry.

4. Sustainable operations

Many industries are now focusing on sustainability. You might already know that industries consume a lot of energy. Therefore, sustainability is essential to preserve our natural resources for the next generations. The best thing about improvements in technology is that now manufacturers have options to shift to sustainable operations. It doesn’t mean that it will affect the efficiency of production. All the equipment works fine. The difference is that they don’t use as much power as they did in the past.

The Bottom Line

In the end, we have concluded that various innovations are taking place in the injection molding industry. More innovations would be there in the future too. We hope this article helped you in understanding them more precisely. You are always welcome here if you want to reread the above information.