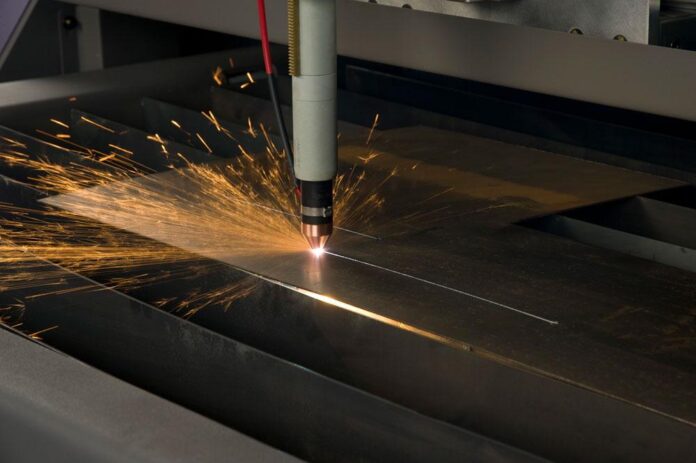

CNC plasma cutting machines have become increasingly popular in recent years, thanks to their ability to precisely cut through various materials quickly and efficiently.

These machines use computer numerical control (CNC) technology to cut through materials like steel, aluminum, and other metals. In this article, we’ll explore the top 6 applications for CNC plasma cutting machines in 2024.

1. Metal Fabrication

CNC plasma cutting machines have transformed the metal fabrication industry by providing a fast and precise way of cutting through various types of metal. These machines use computer numerical control technology to cut through metals such as steel, aluminum, and other metals with high precision.

They have become an essential tool for machine shops in NC, allowing them to produce metal parts and components with greater efficiency, speed, and accuracy. In this section, we will explore the different applications in metal fabrication.

Custom Parts Manufacturing

These machines are widely used in the manufacturing of custom metal parts for various industries. These machines can quickly cut through different types of metals, creating precise shapes and sizes required for metal components.

Custom parts manufacturing using them results in faster production times, lower costs, and greater precision compared to traditional manufacturing methods.

Structural Fabrication

They are used to create custom metal structures such as beams, columns, and trusses for buildings and bridges. They can cut through metals of different thicknesses and sizes, creating custom designs with high accuracy.

3. Art and Decor

CNC plasma cutting machines can also be used in the art and decor industry. These machines can create intricate designs and patterns in metal, which can be used to create sculptures, wall art, and other decorative items. They have become popular in the art industry due to their ability to create custom pieces quickly and with great precision.

4. HVAC Ducting

They have revolutionized the HVAC ducting industry by offering a fast and efficient way of cutting sheet metal into precise shapes and sizes required for ducting systems. In this part, we will explore the different applications of HVAC ducting.

Precision Cutting

These appliances are highly accurate, allowing for the creation of precise shapes and sizes required for HVAC ducting. These devices can quickly cut through sheet metal to create components such as elbows, tees, and transitions with the accuracy required for ducting systems.

Time and Cost Efficiency

They can cut through sheet metal quickly and efficiently, reducing production time and cost compared to traditional methods. These devices offer a highly automated process that reduces labor and material waste while increasing precision, resulting in higher-quality ducting systems at a lower cost.

Custom Fabrication

They can create custom designs for HVAC ducting components, allowing for the creation of unique systems that are tailored to specific buildings and environments. These apparatuses can create custom shapes and sizes that may be challenging or impossible to produce with traditional methods.

Repairs and Replacements

CNC plasma cutting machines can be used to create replacement parts for damaged or worn-out ducting components. This reduces the cost of replacement and speeds up the repair process by quickly shortening the required components with high precision.

Signage

CNC plasma cutting machines can also be used to create custom signs for businesses and organizations. These machines can cut through various materials, such as metal, acrylic, and wood, to create unique and eye-catching signage.

CNC plasma cropping machines can create precise shapes and designs quickly, allowing for the creation of custom signage at a faster pace than traditional methods.

5. Industrial Cutting

CNC plasma cutting machines are widely used in the industrial sector for etching various materials like metal, rubber, and plastic. They are used to create components for manufacturing, cropping gaskets, and other industrial applications. CNC plasma-cutting machines are popular in the industrial sector due to their speed, precision, and efficiency.

6. Automotive

CNC plasma cutting machines have a wide range of applications in the automotive industry, where precision and speed are crucial. These apparatuses are used to cut through various materials, such as steel and aluminum, to create custom parts and components for vehicles. In this section, we will explore the different applications of CNC plasma-cutting devices in the automotive industry.

Custom Parts Manufacturing

CNC plasma cutting appliances are used in the manufacturing of custom parts for cars, trucks, and other vehicles. These devices can quickly cut through different types of metals, such as aluminum and steel, to create precise shapes and sizes required for automotive components. Custom parts manufacturing using CNC plasma cutting appliances results in faster production times, lower costs, and greater precision compared to traditional manufacturing methods.

Restoration and Repair

CNC plasma cutting machines can be used in the restoration and repair of vintage cars and trucks. These devices can recreate missing or damaged parts with high accuracy, using precise measurements and designs.

Restoration and repair using CNC plasma cutting apparatuses can restore classic vehicles to their original condition while maintaining the integrity of the original design.

Prototype Development

CNC plasma cutting machines are also used in the development of vehicle prototypes. These apparatuses can create precise models of vehicle components, allowing engineers to test and refine designs before mass production. Prototype development using CNC plasma cutting appliances can save time and money by identifying design flaws early in the development process.

Motorsports

CNC plasma cutting devices are used in the manufacturing of parts for motorsports vehicles, such as race cars and motorcycles. These apparatuses can create lightweight, high-strength parts that can withstand the extreme conditions of motorsports.

The precision and speed of CNC plasma cutting machines make them an ideal tool for the manufacture of parts for motorsports vehicles.

Conclusion

CNC plasma cutting machines have become increasingly popular in various industries due to their ability to quickly and efficiently cut through various materials. From metal fabrication to automotive manufacturing, these machines have numerous applications that can help businesses save time and money while increasing precision and efficiency.

If you’re considering investing in a CNC plasma-cutting machine, be sure to explore the various applications and industries that can benefit from this technology.